PRODUCTS

Sintered Wire Cloth

Sintered Wire Cloth Laminate

Diffusion-bonded (sintered) layers of cloth improve the filtration properties and the usability of individual layers of filtration cloth. SinterPore™ allows building filters, that combine new properties with the advantages of metal filter cloths.

- A precise, robust pore geometry by a firm bond

- Heat and corrosion-resistance

- Favourable forming property and weldability

- Favourable cleanability and reusabililty

- Definable porosity of the laminate

Porous Metal Filters Sintered Wire Cloth Laminate is used in many industries including Automotive and Plant Oil Extraction.

SINTERPORE® Single Layer Sintered Wire Cloth (SLS) Products

With un-sintered material, the interlocking of the weave is the only strength factor which prevents wire movement. Sintered wire cloth makes the geometry of the original weave permanent, and therefore the pore size and absolute filter rating of the medium permanent as well.

Sintered Wire Cloth Standard Products and Common Uses

- Standard 2- and 3-layer SinterPore® fluidizing laminates with customer-specific permeability flow rates are often used in bulk powder handling.

- Standard 5-layer SinterPore® laminates are often used in the pharmaceutical, polymer, and liquid and gas filtration industries.

Standard Layer Filter

(MM)

INCHES (+/- 0.003”)

L/M² X SEC. (DP= 2 MBAR)

(MM)

INCHES (+/- 0.003”)

SINTERPORE® Multi Layered Sintered Wire Cloth (MLS) Products

SinterPore® Multi-Layered Sintered (MLS) media is constructed of multiple layers of stainless wire mesh and is designed for precise, controlled porosity, uniform pore sizes, and distributions. SinterPore® MLS laminates are permanently bonded under precise diffusion bonding (metal sintering) conditions yielding robust monolithic materials used in a wide variety of engineering applications ranging from industrial filtration to aerospace transpiration cooling.

Standard Products and Common Uses

- Standard 2- and 3-layer SinterPore® fluidizing laminates with customer-specific permeability flow rates are often used in bulk powder handling.

- Standard 5-layer SinterPore® laminates are often used in the pharmaceutical, polymer, and liquid and gas filtration industries.

Applications

- Oil and Gas

- Pharmaceutical

- Aerospace

- Polymer

- Chemical Process

- Bulk Powder Handling (fluidization)

- Industrial Filtration

Features and Benefits:

- Heat and wear resistance

- Cleanability and reusability

- Fixed Pore Geometry

- Robust Non-Compressible Media

Specifications

- Standard Sheet Sizes: 18”x48”, 24”x48”. Custom sizes available upon request. Maximum laminate size without welding is 24”x60” (larger sheets available with welds, maximum panel width with welds 120”).

- Standard Alloys: 304, 304L, 316, 316L, Alloy20 (also available in Inconel 600 and 625, Monel, and Hastalloy upon request).

SINTERPORE® Fluidizing Media Filters

(SCFM/SF @ 2” W.C.)

(inches)

SINTERPORE® Metal Mesh and Premium Sand Control Screen Specification Summary

MICRON RATING

(INCHES)

(MICRONS)

AIR PERMEABILITY

POROSITY %

STRENGTH

EASY TO CLEAN

ROBUST & DURABLE

BACK WASHABLE

ABRASION & CORROSION RESISTANT

CUSTOM DESIGN

UNIFORM FLOW

Porous Metal Filters is ISO 9001 Certified, and all our products are manufactured to the highest quality standards. Our staff is available to help you design the wire filtration product that will meet your design requirements and budget. Contact us today for more information about our products.

PMF Brochures and Product Literature

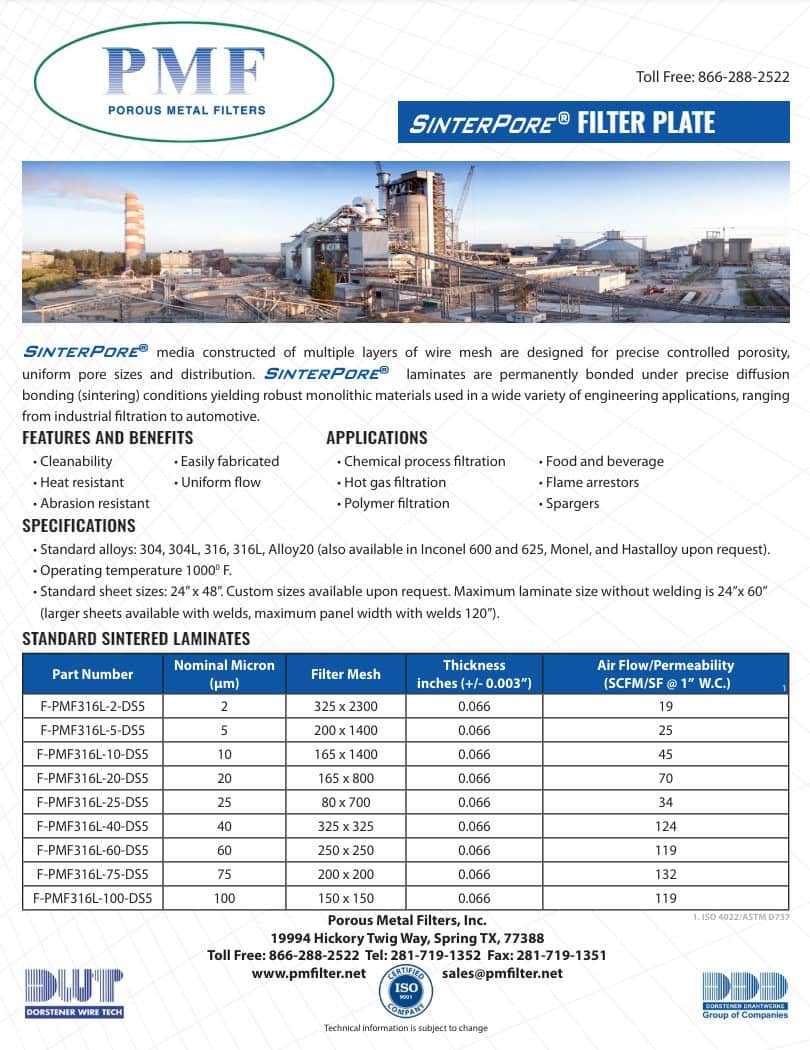

Filter Plate

2-page flyer with features and benefits, applications, and specifications (PDF)

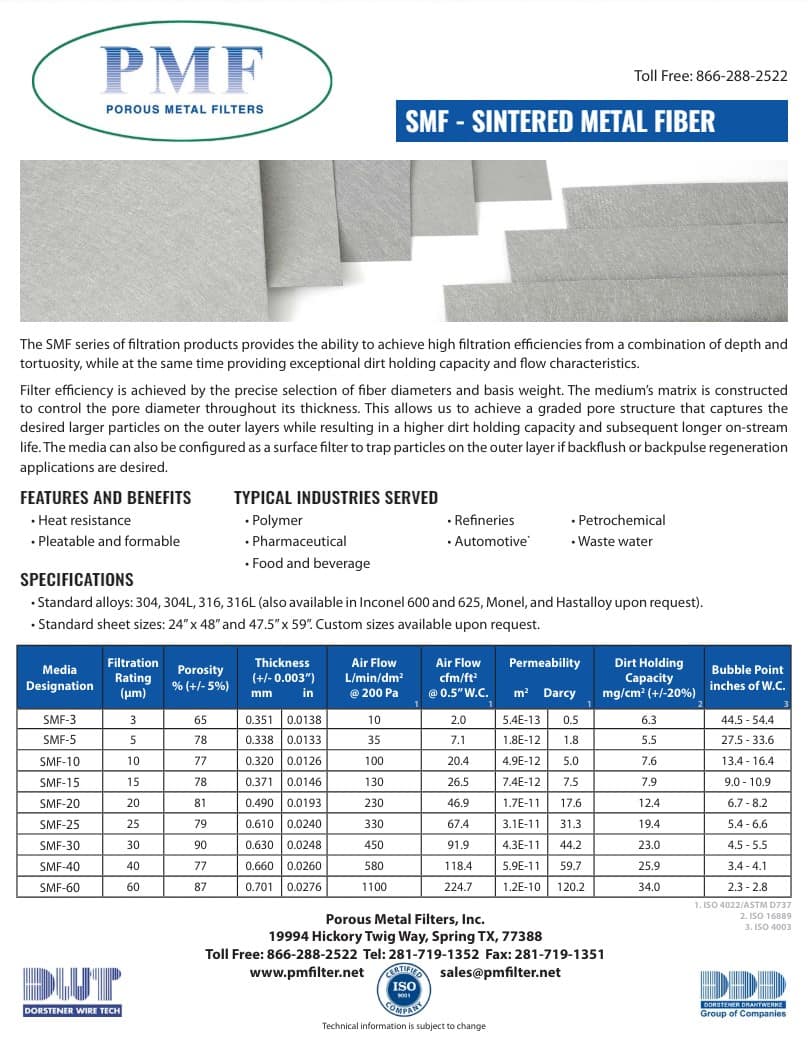

Sintered Metal Fiber

2-page flyer with features and benefits, applications, and specifications (PDF)

Metallic Filter Cartridges

2-page flyer with features and benefits, applications, and specifications (PDF)

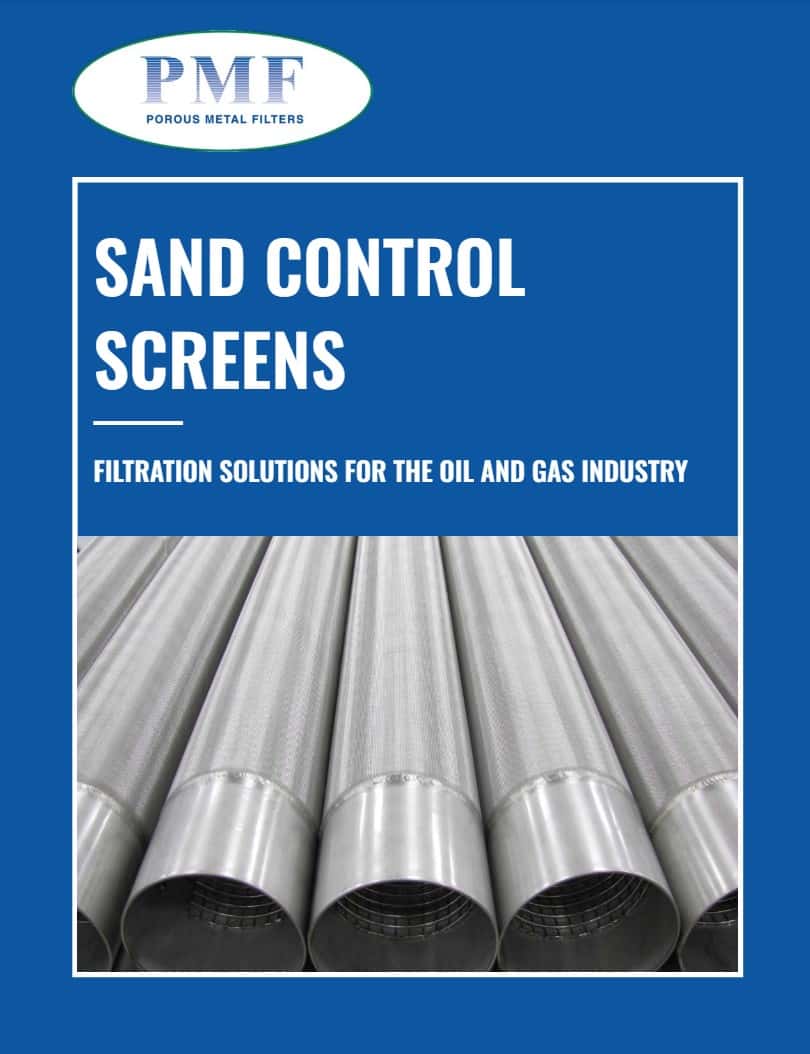

Sand Control Screens

4-page brochure with features and benefits, applications, and specifications (PDF)

Fluidizing Media

2-page flyer with features and benefits, applications, and specifications (PDF)

Polymer Filtration

2-page flyer with features and benefits, applications, and specifications (PDF)

Power Generation

2-page flyer with features and benefits, applications, and specifications (PDF)

Ballast Water Filters

2-page flyer with features and benefits, applications, and specifications (PDF)

Your One-Stop Solution for Advanced Filtration and Metal Fabrication

We invite you to explore and discover how PMF can transform your filtration and separation challenges into opportunities for growth and success. Join us on this exciting journey as we reshape industries, one innovative filter at a time. Together, let's unlock the true potential of porous metal filtration. Give us a call, stop by for a free tour of the facility, or fill out our contact form and we'll gladly assist you.

Find Exactly What You Need

COMPANY

INDUSTRIES & APPLICATIONS

Automotive

Bulk & Powder Handling

Chemical Processing

Chromatography

Crude Oil Processing

Filtration Industry

Fuel Cells & Re-Formers

Gasification

Hot Gas Filtration

Industrial Filtration

Industrial Water Management

Irrigation Filtration

Liquid Filtration

Noise Abatement

Oil & Gas

Pharmaceutical

Plant Oil Extraction

Power Generation

Renewable Energy

Aerospace Filters

Ballast Water Filters

Chemical & Industrial Spargers

Chromatography Frits

Demineralizer Filters

Flame/Spark Arrestors

Flood Filters

Fluidizing Media

Gasification Filters

Hot Gas Filters

Irrigation Filters

Metallic Filter Cartridges

Metallic Memberane Support for Hydrogen

Nutsche Filters

Porous Metal Plate

Sand Screens

Sintered Metal Fiber

Sintered Wire Cloth

Temporary Strainers & Baskets

CAPABILITIES

Porous Metal Filters provides solutions for industrial filtration, separation, flow control, noise reduction, powder fluidization, and other applications through our SINTERPORE® brand of diffusion bonded (sintered) porous metal materials. Porous Metal Filters’ goal is to utilize its extensive experience to promote porous metal filters for the next generation of advanced filtration and separation products.

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(833) 707-9222 toll free

(281) 719-1352 local

(281) 719-1351 fax