MANUFACTURING CAPABILITIES

Punching and Stamping Services

Punching and Stamping Services

Punching is a process that uses a CNC machine to shear, notch, and punch angles and flat bars. Porous Metal Filters utilizes state-of-the-art equipment to plasma cut, punch, drill, and tap metal components to produce items in a cost effective manner.

Punching holes with a punch press is one of the most mature technologies in metal fabrication, and yet it’s still one of the most misunderstood. Modern machines and tooling have turned the punch press into the Swiss army knife of the fab shop. It punches holes, just a few here and there or in a dense perforation. It cuts large panels. It forms louvers, embosses, and other complex shapes, and in some cases bends flanges several inches high.

Still, because the punch press can do so much, processing variables abound, and if they’re not accounted for, part quality and throughput can suffer. Understanding a few punching fundamentals can go a long way in ensuring that the multitude of processing variables remain well under control.

Our sheet and plate machines have computer numerical controls (CNC) that allow for production repeatability and are programmed from CAD software to reduce errors. Typical material thicknesses for punching is ½” thick and below.

Porous Metal Filters offers CNC metal forming and bending services to produce components and fabricated parts for subassemblies. From simple 90° bends to complex sequences with multiple bends, our press brakes can form small and large parts.

Technology, skill, and process controls allow formability and repeatability to meet customer demand. PMF can handle a wide range of material grades, thickness, and sizes.

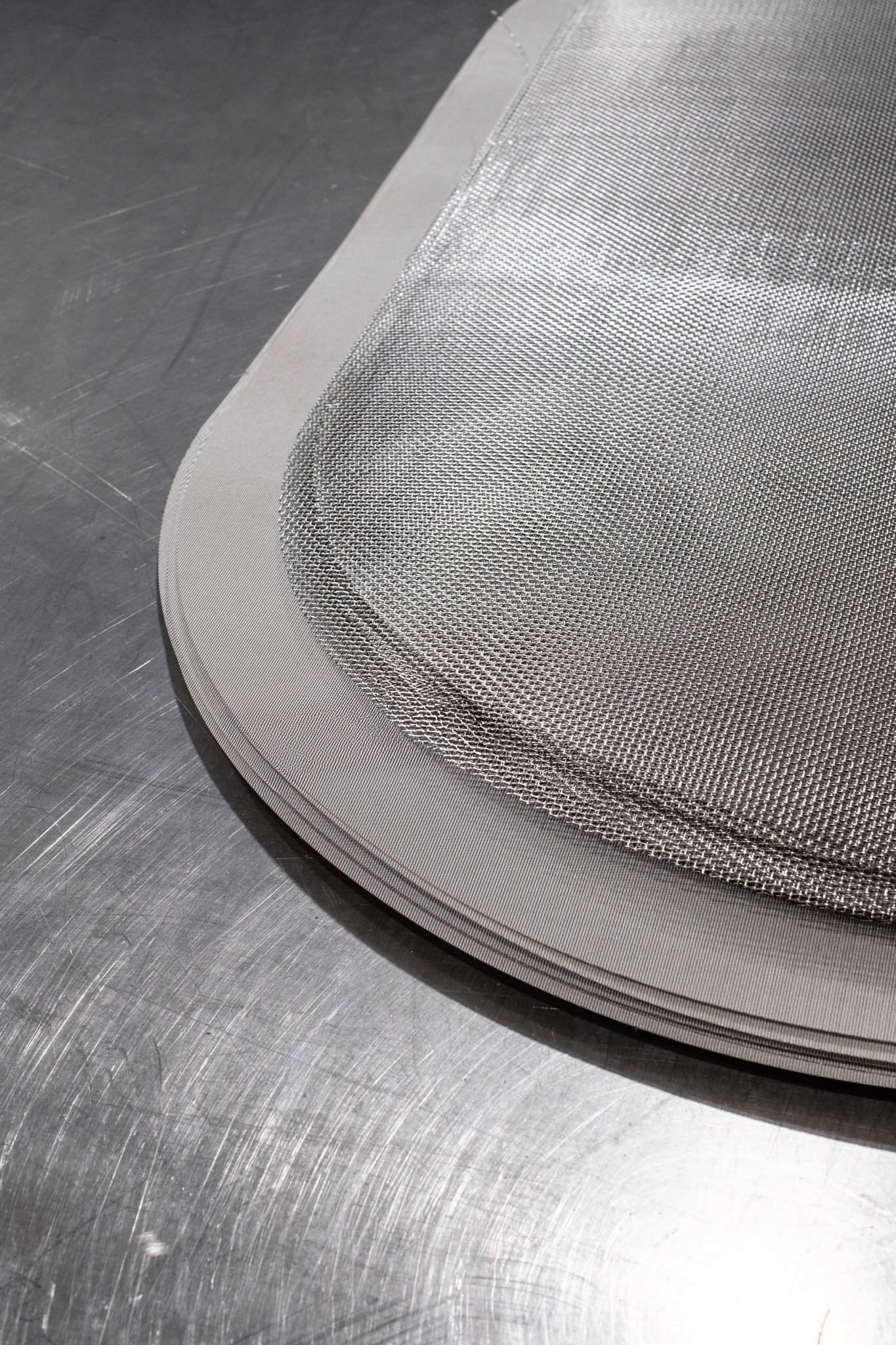

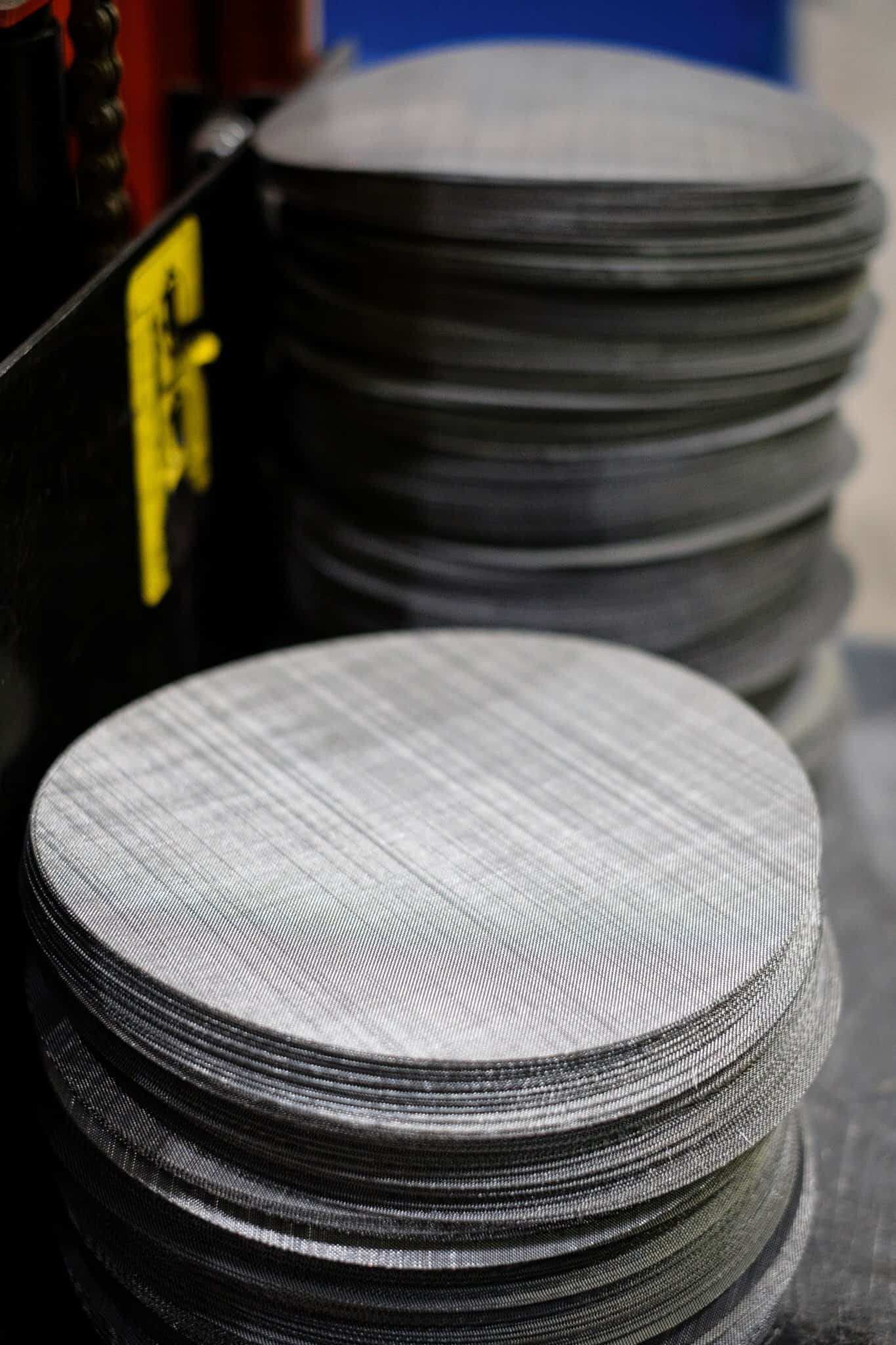

Shaping & Punching Wire Mesh

DWT utilizes shaping and punching to provide custom shapes to meet clients’ specifications and requirements. We offer economical stamped parts in many configurations as well as laser cut or plasma cut parts for prototypes and small run parts. For stampings, we have a wide range of standard round dies. If you are unsure of your needs, or want additional information on our cutting or stamping capabilities, please contact us to learn more.

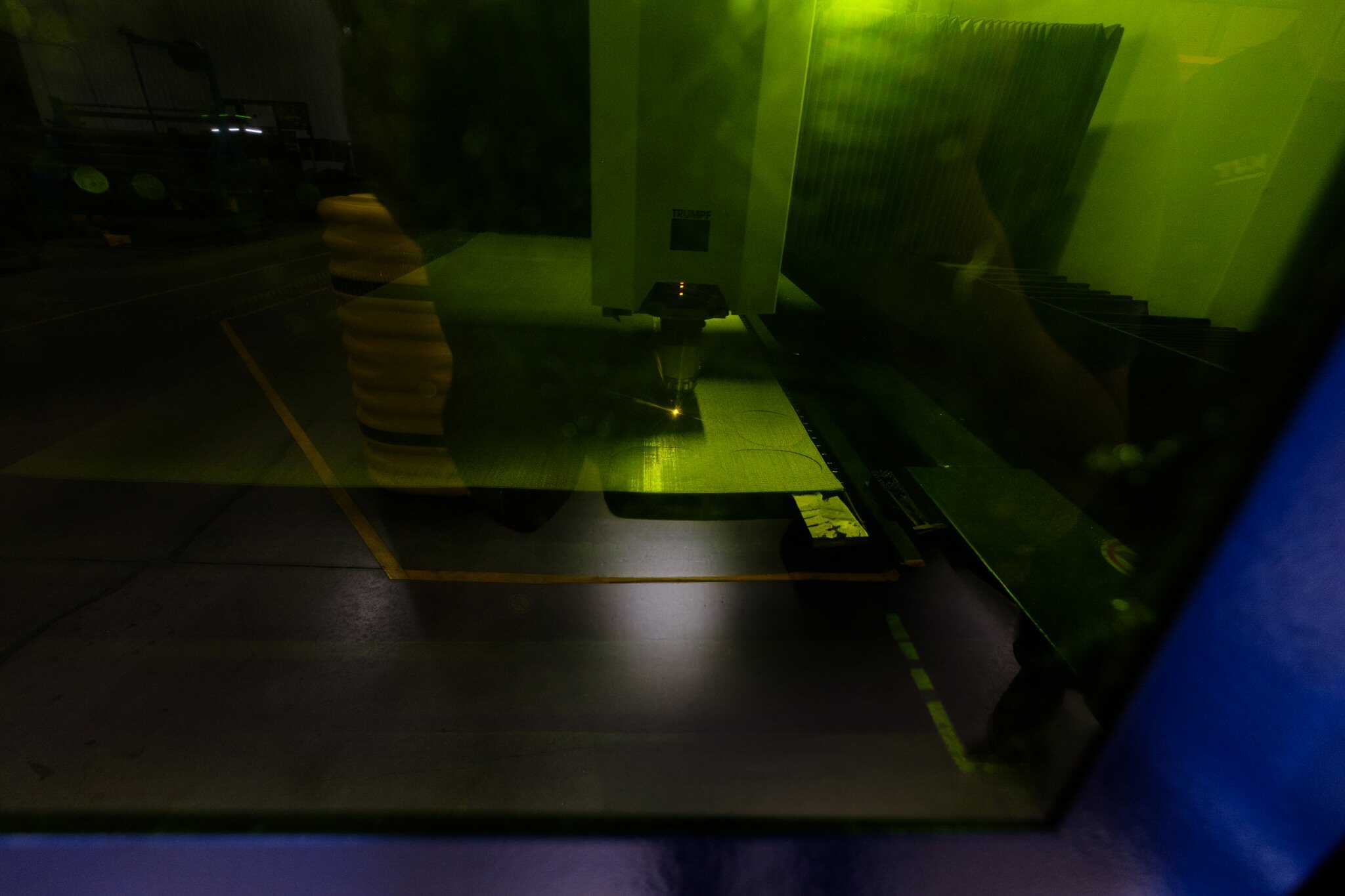

Custom Tooling

Custom tooling is available made to order. PMF has in house tooling capabilities helping to save time and cost. We also offer laser cutting for rapid prototyping.

Porous Metal Filters is ISO 9001 Certified, and all our products are manufactured to the highest quality standards. Our staff is available to help you design the wire filtration product that will meet your design requirements and budget. Contact us today for more information about our products.

Your One-Stop Solution for Advanced Filtration and Metal Fabrication

We invite you to explore and discover how PMF can transform your filtration and separation challenges into opportunities for growth and success. Join us on this exciting journey as we reshape industries, one innovative filter at a time. Together, let's unlock the true potential of porous metal filtration. Give us a call, stop by for a free tour of the facility, or fill out our contact form and we'll gladly assist you.

Find Exactly What You Need

COMPANY

INDUSTRIES & APPLICATIONS

Automotive

Bulk & Powder Handling

Chemical Processing

Chromatography

Crude Oil Processing

Filtration Industry

Fuel Cells & Re-Formers

Gasification

Hot Gas Filtration

Industrial Filtration

Industrial Water Management

Irrigation Filtration

Liquid Filtration

Noise Abatement

Oil & Gas

Pharmaceutical

Plant Oil Extraction

Power Generation

Renewable Energy

Aerospace Filters

Ballast Water Filters

Chemical & Industrial Spargers

Chromatography Frits

Demineralizer Filters

Flame/Spark Arrestors

Flood Filters

Fluidizing Media

Gasification Filters

Hot Gas Filters

Irrigation Filters

Metallic Filter Cartridges

Metallic Memberane Support for Hydrogen

Nutsche Filters

Porous Metal Plate

Sand Screens

Sintered Metal Fiber

Sintered Wire Cloth

Temporary Strainers & Baskets

CAPABILITIES

Porous Metal Filters provides solutions for industrial filtration, separation, flow control, noise reduction, powder fluidization, and other applications through our SINTERPORE® brand of diffusion bonded (sintered) porous metal materials. Porous Metal Filters’ goal is to utilize its extensive experience to promote porous metal filters for the next generation of advanced filtration and separation products.

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(833) 707-9222 toll free

(281) 719-1352 local

(281) 719-1351 fax