PRODUCTS

Metallic Filter Cartridges

Metallic Filter Cartridges

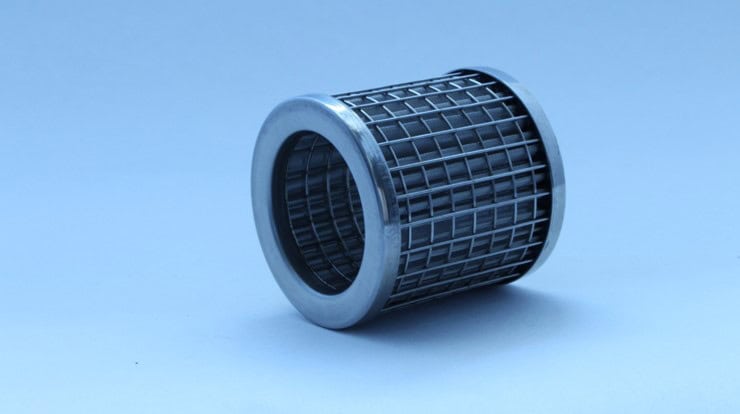

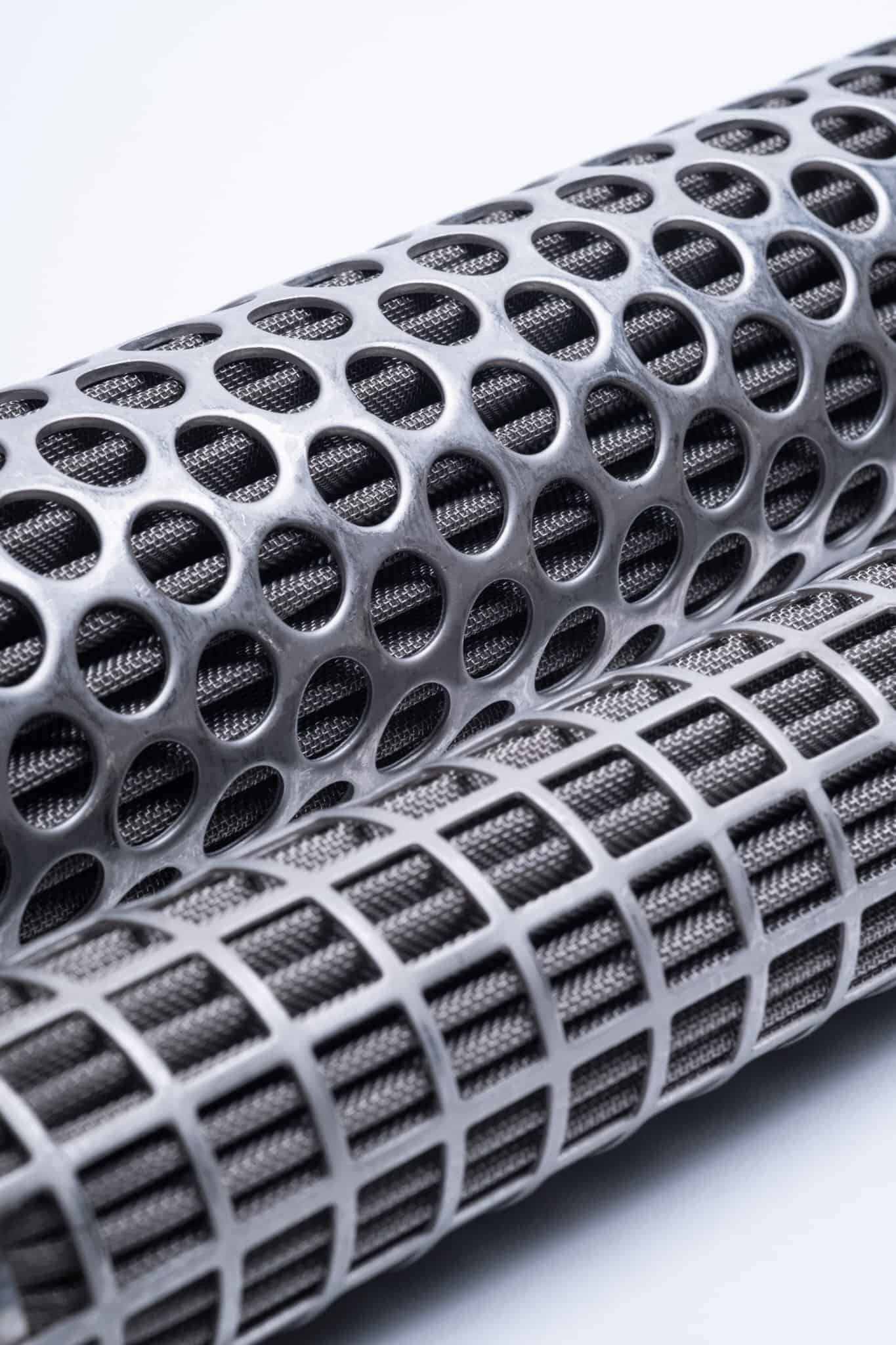

Porous Metal Filters metallic filter cartridges provide the optimum filtration solution for fluids and gases in high temperature and high flow rate applications. Available in a cylindrical or pleated design, cleanable stainless steel cartridges are the logical choice when natural and synthetic media cartridges cannot meet aggressive process conditions.

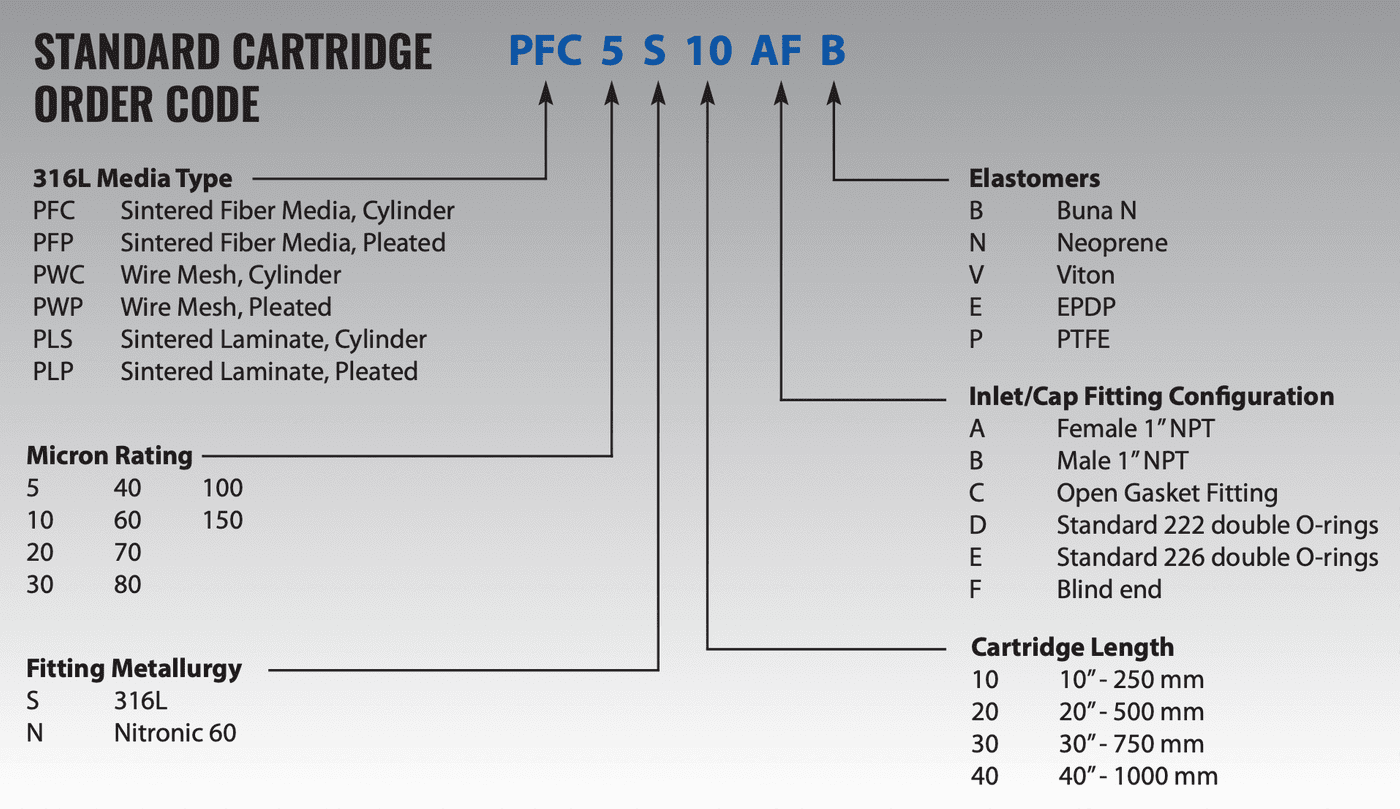

PMF reusable 304 and 316 grade stainless steel cartridges offer versatility of choice with ten nominal particle removal ratings, four standard lengths and a variety of end configurations and seal materials.

PMF’s SINTERPORE® sintered wire cloth and sintered metallic fiber filter media are designed to meet the challenges faced by today’s industries. Porous Metal Filter’s metallic filter cartridges are ideal for new installations or optimum retrofit to existing filter housings and systems. The metallic filter cartridges serve equally well for liquid or gas service.

Porous Metal Filters Metallic Filter Cartridges are used in applications acvross many industries including Bulk and Powder Handling, Chemical Processing, Filtration Industry, Fuel Cells and Re-Formers, Industrial Water Management, Noise Abatement, Power Generation, and Renewable Energy.

Features and Benefits of SINTERPORE® Metallic Filter Cartridges

- The main benefits of sintered metallic filter cartridges are their high heat resistance and ability to be cleaned and re-used. This results in significant cost savings over other types of filter materials.

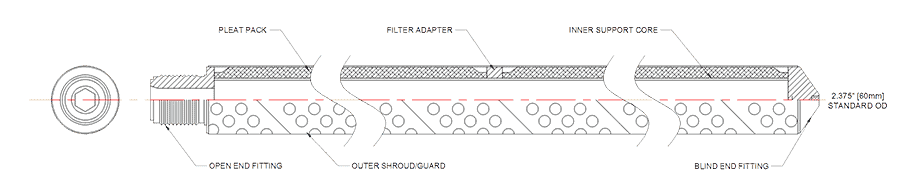

- All-welded construction and sintered media results in excellent mechanical strength and a consistent pore size under all conditions.

- The filters are available in a wide range of micron sizes and pore structures that can be tailored to specific applications. Media pore size, structure and metallurgy can be further customized for the most demanding applications.

- Metallic filters feature low pressure drop and back-wash/pulse cleaning capabilities.

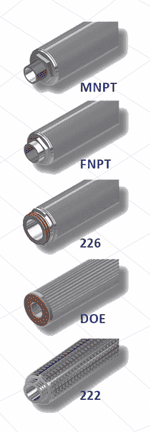

Any standard arrangement of end connections and seal configurations can be supplied. Custom connections are available upon request. - Optimization of these points have a tremendous impact on capital and operating costs in any process. PMF’s fundamental understanding of filtration concepts, technologies, quality control and manufacturing, as well as the end users basic filtration needs will make that optimization possible.

What Separates a Great Filter Manufacturer From the Others?

- Exceptional customer service

- Fast and reliable information Technical information is subject to change

- Product quality

- Professional and positive attitude

We welcome the opportunity to help with your industrial filter needs.

Porous Metal Filters is ISO 9001 Certified, and all our products are manufactured to the highest quality standards. Our staff is available to help you design the wire filtration product that will meet your design requirements and budget. Contact us today for more information about our products.

PMF Brochures and Product Literature

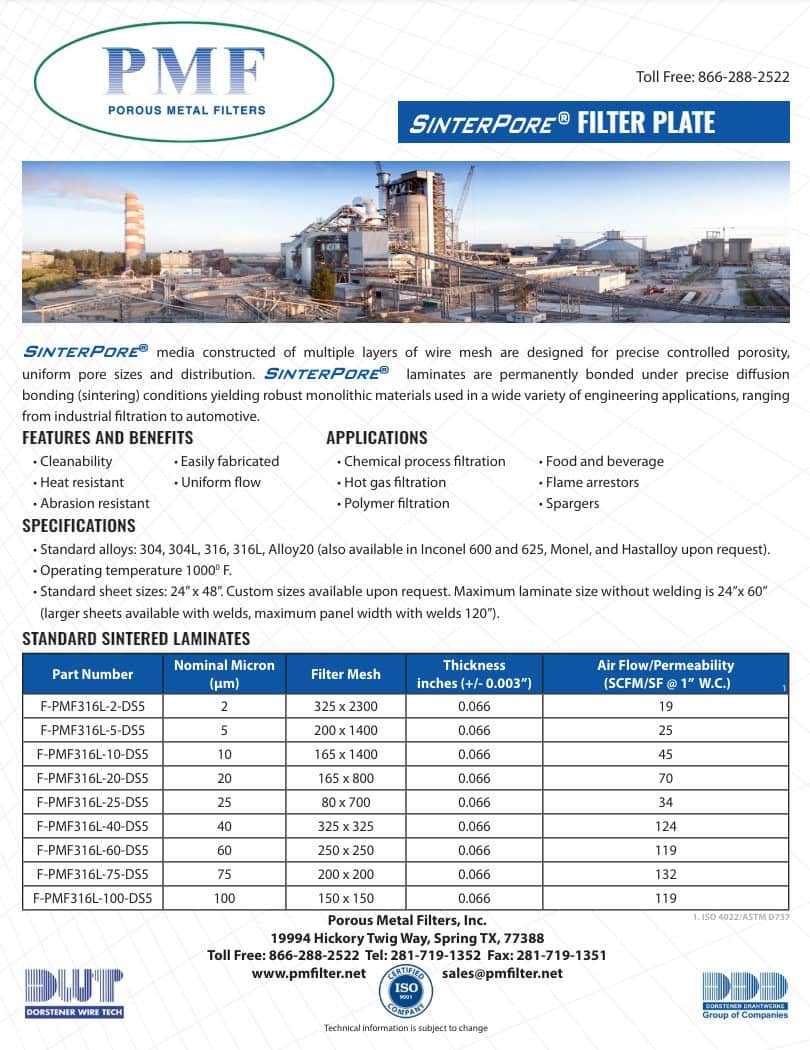

Filter Plate

2-page flyer with features and benefits, applications, and specifications (PDF)

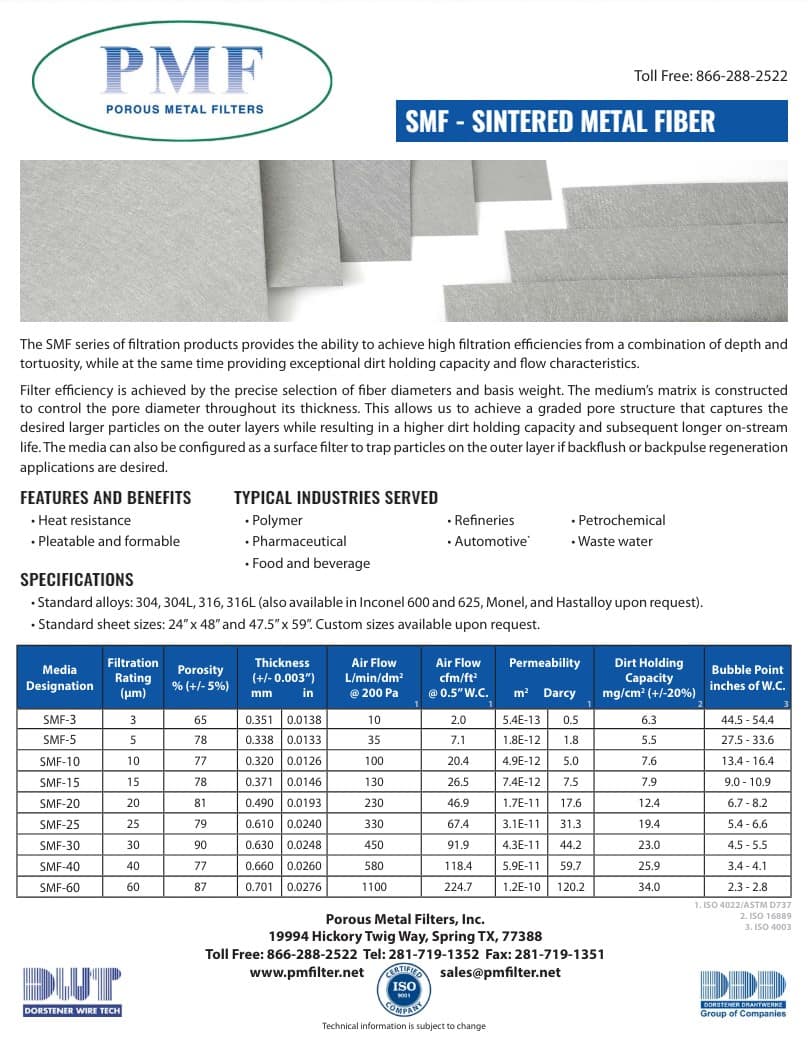

Sintered Metal Fiber

2-page flyer with features and benefits, applications, and specifications (PDF)

Metallic Filter Cartridges

2-page flyer with features and benefits, applications, and specifications (PDF)

Sand Control Screens

4-page brochure with features and benefits, applications, and specifications (PDF)

Fluidizing Media

2-page flyer with features and benefits, applications, and specifications (PDF)

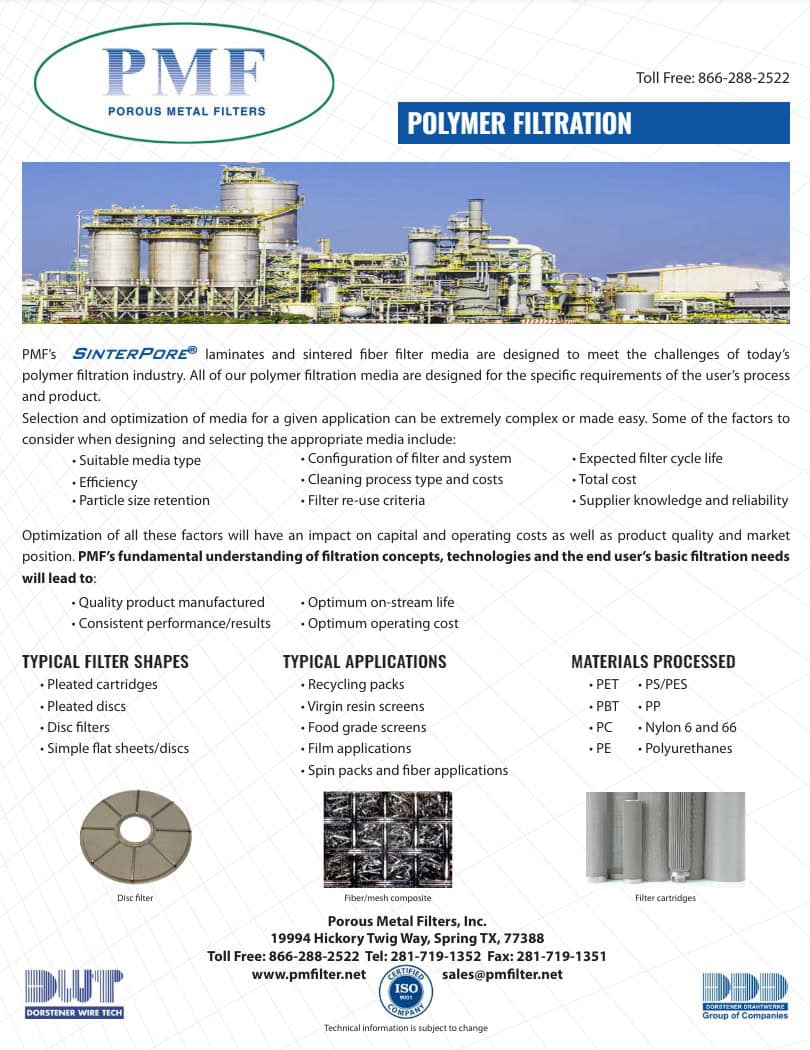

Polymer Filtration

2-page flyer with features and benefits, applications, and specifications (PDF)

Power Generation

2-page flyer with features and benefits, applications, and specifications (PDF)

Ballast Water Filters

2-page flyer with features and benefits, applications, and specifications (PDF)

Your One-Stop Solution for Advanced Filtration and Metal Fabrication

We invite you to explore and discover how PMF can transform your filtration and separation challenges into opportunities for growth and success. Join us on this exciting journey as we reshape industries, one innovative filter at a time. Together, let's unlock the true potential of porous metal filtration. Give us a call, stop by for a free tour of the facility, or fill out our contact form and we'll gladly assist you.

Find Exactly What You Need

COMPANY

INDUSTRIES & APPLICATIONS

Automotive

Bulk & Powder Handling

Chemical Processing

Chromatography

Crude Oil Processing

Filtration Industry

Fuel Cells & Re-Formers

Gasification

Hot Gas Filtration

Industrial Filtration

Industrial Water Management

Irrigation Filtration

Liquid Filtration

Noise Abatement

Oil & Gas

Pharmaceutical

Plant Oil Extraction

Power Generation

Renewable Energy

Aerospace Filters

Ballast Water Filters

Chemical & Industrial Spargers

Chromatography Frits

Demineralizer Filters

Flame/Spark Arrestors

Flood Filters

Fluidizing Media

Gasification Filters

Hot Gas Filters

Irrigation Filters

Metallic Filter Cartridges

Metallic Memberane Support for Hydrogen

Nutsche Filters

Porous Metal Plate

Sand Screens

Sintered Metal Fiber

Sintered Wire Cloth

Temporary Strainers & Baskets

CAPABILITIES

Porous Metal Filters provides solutions for industrial filtration, separation, flow control, noise reduction, powder fluidization, and other applications through our SINTERPORE® brand of diffusion bonded (sintered) porous metal materials. Porous Metal Filters’ goal is to utilize its extensive experience to promote porous metal filters for the next generation of advanced filtration and separation products.

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(833) 707-9222 toll free

(281) 719-1352 local

(281) 719-1351 fax