PRODUCTS

Gasification Filters

Gasification Filters

Gasification and pyrolysis are advanced processes that transform carbon-rich materials such as coal, petroleum coke, biomass, municipal waste, wood chips, and automotive tires through high-temperature reactions. Gasification occurs in a controlled atmosphere with limited oxygen, while pyrolysis happens in the absence of oxygen, resulting in the production of syngas or synthetic natural gas. This syngas serves as a more energy-efficient fuel option than direct combustion of the original feedstock, delivering a higher calorific value. Additionally, syngas can be converted into methanol, hydrogen, or utilized in the production of synthetic fuels via the Fischer Tropsch process.

Various downstream processes, including catalysis, further yield chemical feedstocks for intermediate products and essential end-use materials such as fertilizers. The filtration of solid waste generated during gasification and pyrolysis can occur at different stages employing various methods, with gas filtration options including the use of filter elements or cyclones before the heat exchanger at elevated temperatures of 800°C to 1,000°C, after the heat exchanger at mid-range temperatures of 320°C to 650°C, or through extensive cooling with wet scrubbing systems where temperatures drop below 250°C.

Porous Metal Filters brings extensive expertise in filtration systems utilized in IGCC gasification processes for coal and petroleum coke. Additionally, we specialize in the design and manufacturing of filtration and separation equipment for applications such as PFBC, biomass, and pelletized municipal solid waste. Our permanent metal media filtration solutions deliver exceptional performance, ensuring both high separation efficiency and excellent cleanability. Our systems are engineered to operate effectively across a wide range of pressure and temperature conditions, consistently outperforming alternative technologies.

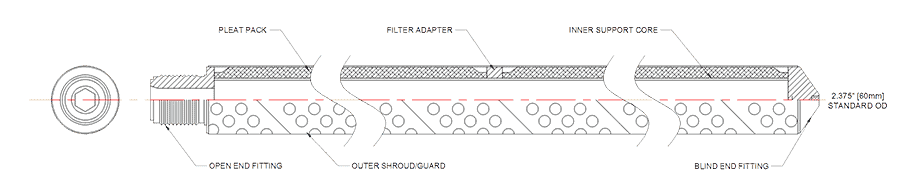

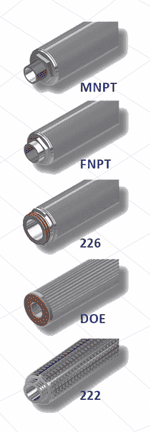

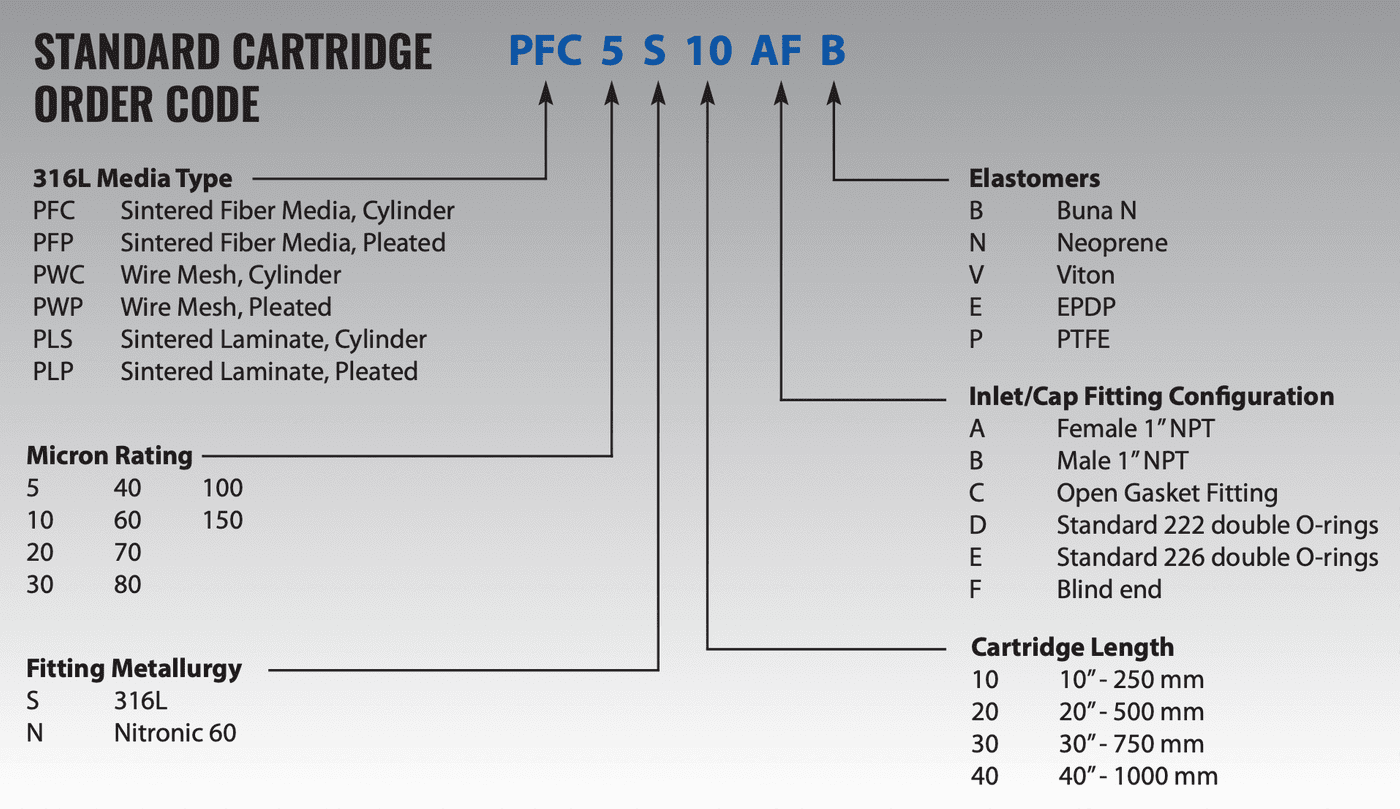

PMF’s SINTERPORE® sintered wire cloth and sintered metallic fiber filter media are designed to meet the challenges for gasification filters faced by today’s chemical process industry. PMF gasification filters and filter cartridges are ideal for new installations or optimum retrofit to existing filter housings and systems. The gasification filters serve equally well for liquid or gas service.

Porous Metal Filters Gasification Filters are used in many industries and appliactions including Fuel Cells and Re-Forming, Gasification, Noise Abatement, Power Generation, and Renewable Energy.

Features and Benefits of SINTERPORE® Gasification Filter Cartridges

- The main benefits of sintered metallic gasification filters are their high heat resistance and ability to be cleaned and re-used. This results in significant cost savings over other types of filter materials.

- All-welded construction and sintered media results in excellent mechanical strength and a consistent pore size under all conditions.

- The filters are available in a wide range of micron sizes and pore structures that can be tailored to specific applications. Media pore size, structure and metallurgy can be further customized for the most demanding applications.

- Metallic filters feature low pressure drop and back-wash/pulse cleaning capabilities.

Any standard arrangement of end connections and seal configurations can be supplied. Custom connections are available upon request. - Optimization of these points have a tremendous impact on capital and operating costs in any process. PMF’s fundamental understanding of filtration concepts, technologies, quality control and manufacturing, as well as the end users basic filtration needs will make that optimization possible.

Porous Metal Filters is ISO 9001 Certified, and all our products are manufactured to the highest quality standards. Our staff is available to help you design the wire filtration product that will meet your design requirements and budget. Contact us today for more information about our products.

PMF Brochures and Product Literature

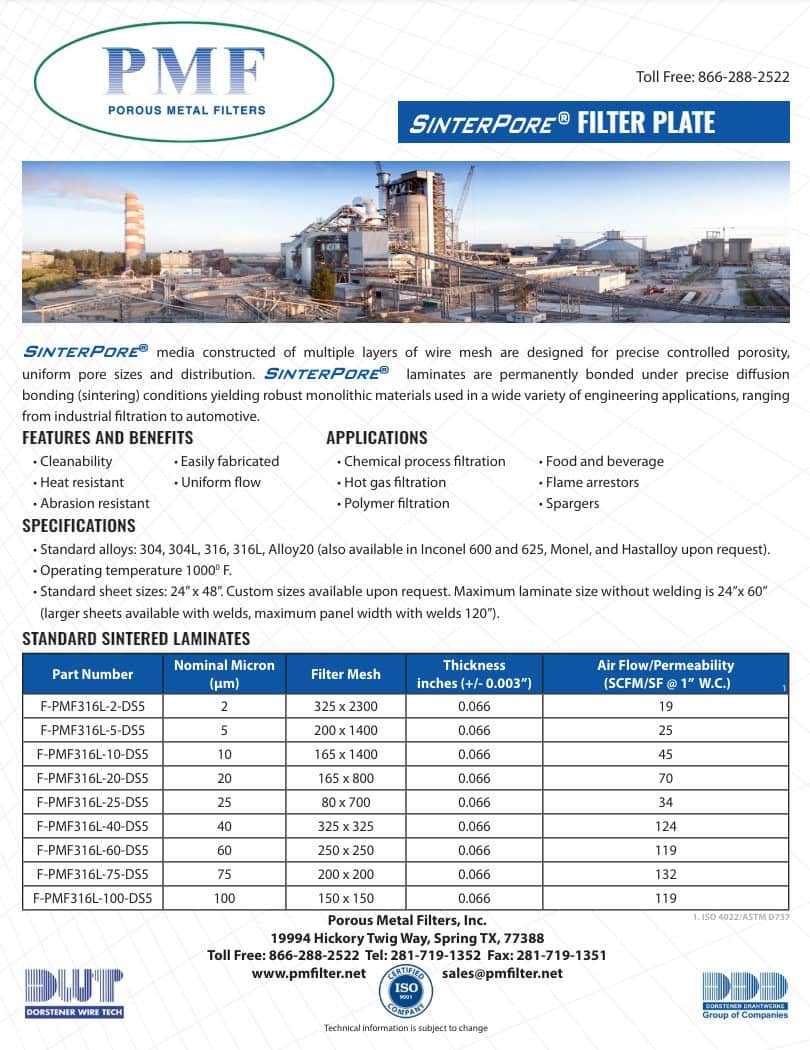

Filter Plate

2-page flyer with features and benefits, applications, and specifications (PDF)

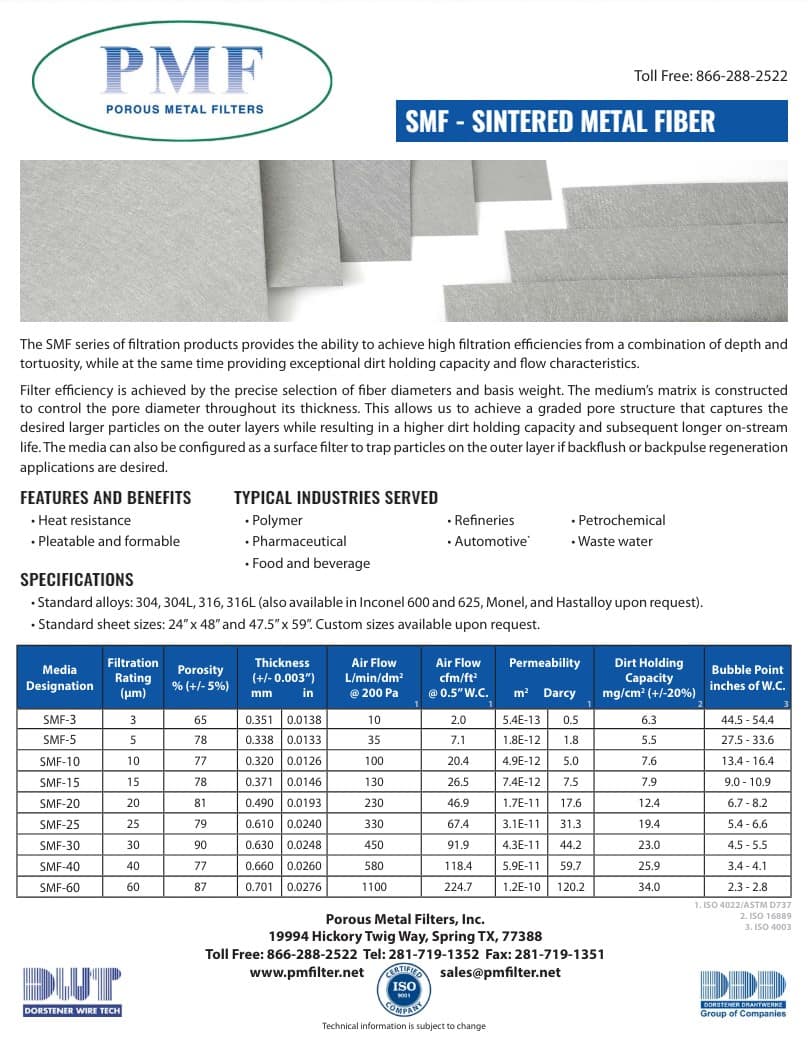

Sintered Metal Fiber

2-page flyer with features and benefits, applications, and specifications (PDF)

Metallic Filter Cartridges

2-page flyer with features and benefits, applications, and specifications (PDF)

Sand Control Screens

4-page brochure with features and benefits, applications, and specifications (PDF)

Fluidizing Media

2-page flyer with features and benefits, applications, and specifications (PDF)

Polymer Filtration

2-page flyer with features and benefits, applications, and specifications (PDF)

Power Generation

2-page flyer with features and benefits, applications, and specifications (PDF)

Ballast Water Filters

2-page flyer with features and benefits, applications, and specifications (PDF)

Your One-Stop Solution for Advanced Filtration and Metal Fabrication

We invite you to explore and discover how PMF can transform your filtration and separation challenges into opportunities for growth and success. Join us on this exciting journey as we reshape industries, one innovative filter at a time. Together, let's unlock the true potential of porous metal filtration. Give us a call, stop by for a free tour of the facility, or fill out our contact form and we'll gladly assist you.

Find Exactly What You Need

COMPANY

INDUSTRIES & APPLICATIONS

Automotive

Bulk & Powder Handling

Chemical Processing

Chromatography

Crude Oil Processing

Filtration Industry

Fuel Cells & Re-Formers

Gasification

Hot Gas Filtration

Industrial Filtration

Industrial Water Management

Irrigation Filtration

Liquid Filtration

Noise Abatement

Oil & Gas

Pharmaceutical

Plant Oil Extraction

Power Generation

Renewable Energy

Aerospace Filters

Ballast Water Filters

Chemical & Industrial Spargers

Chromatography Frits

Demineralizer Filters

Flame/Spark Arrestors

Flood Filters

Fluidizing Media

Gasification Filters

Hot Gas Filters

Irrigation Filters

Metallic Filter Cartridges

Metallic Memberane Support for Hydrogen

Nutsche Filters

Porous Metal Plate

Sand Screens

Sintered Metal Fiber

Sintered Wire Cloth

Temporary Strainers & Baskets

CAPABILITIES

Porous Metal Filters provides solutions for industrial filtration, separation, flow control, noise reduction, powder fluidization, and other applications through our SINTERPORE® brand of diffusion bonded (sintered) porous metal materials. Porous Metal Filters’ goal is to utilize its extensive experience to promote porous metal filters for the next generation of advanced filtration and separation products.

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(833) 707-9222 toll free

(281) 719-1352 local

(281) 719-1351 fax