MANUFACTURING CAPABILITIES

Inspection Services

AccuPore Mesh Analysis by Inspection Services

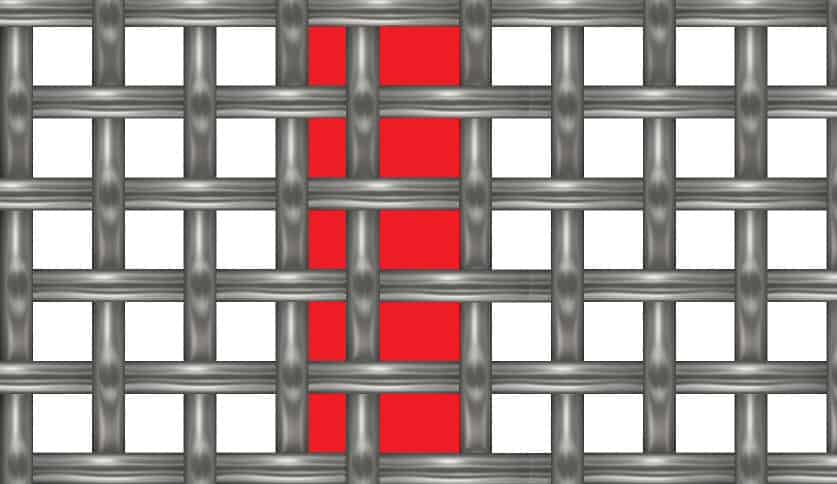

At Porous Metal Filters, we have developed an extensive quality control system to ensure we meet the requirements of our clients. One of our most recent additions to our quality system is an automated visual mesh analysis by inspection of wire cloth. This process is referred to as AccuPore Mesh Analysis by Inspection. This mesh analysis system gives us the ability to detect subtle, unpredictable defects that are inherent in the weaving process.

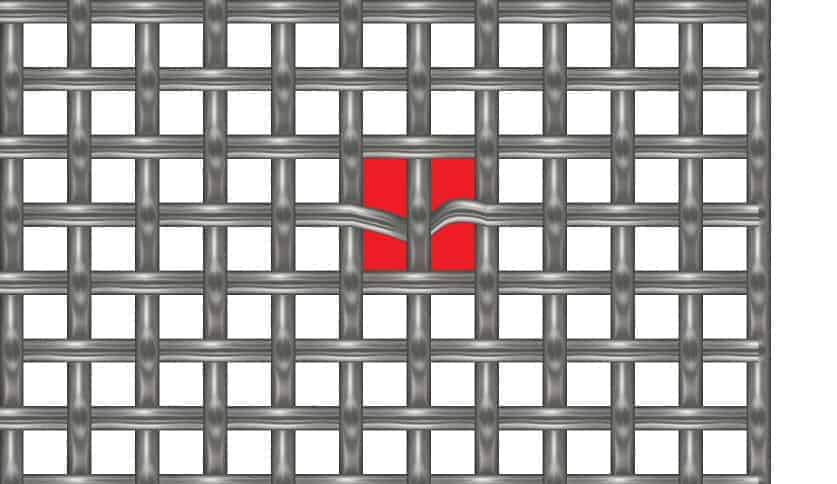

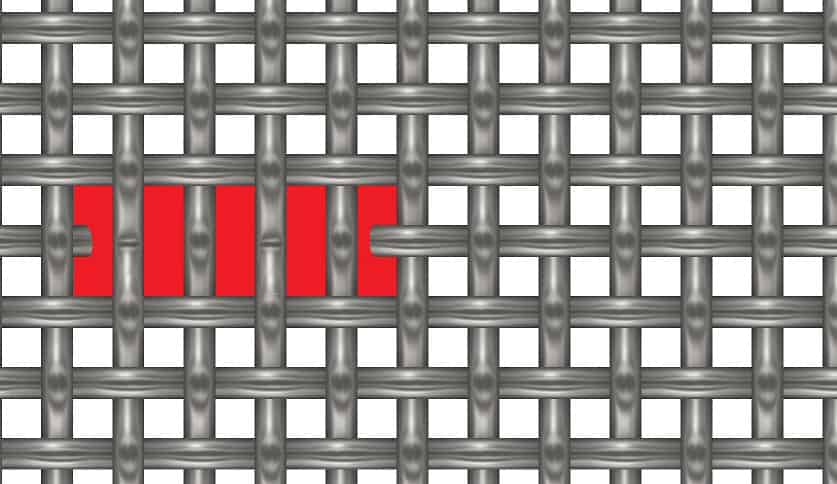

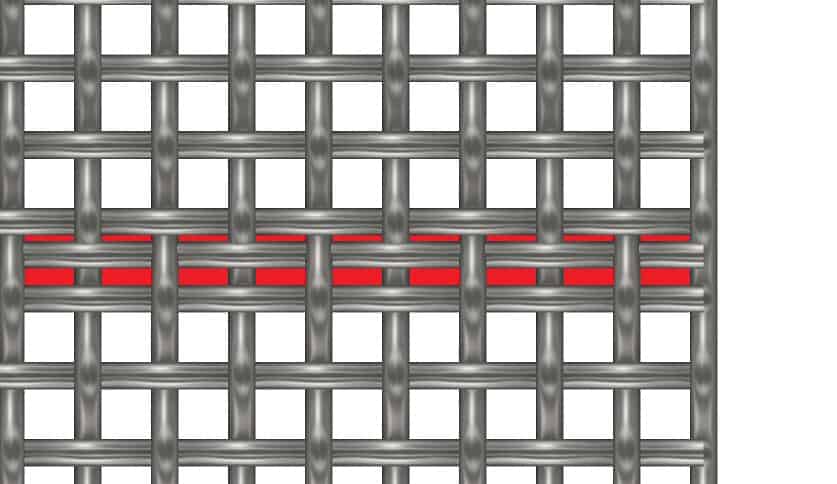

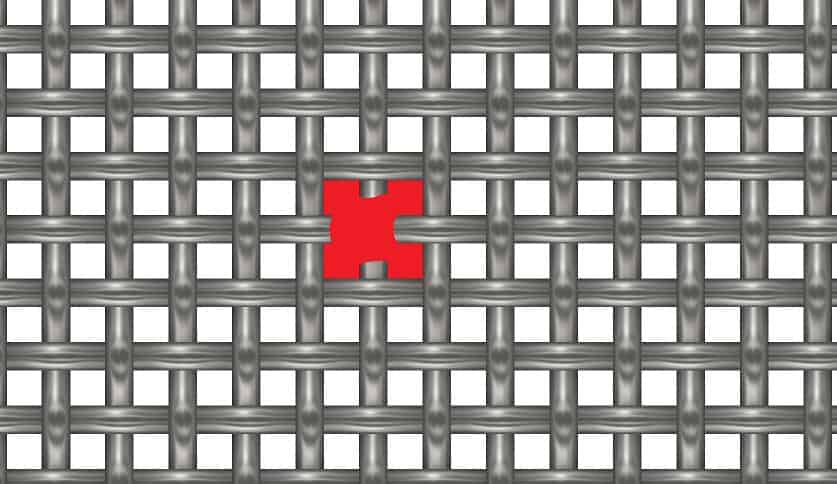

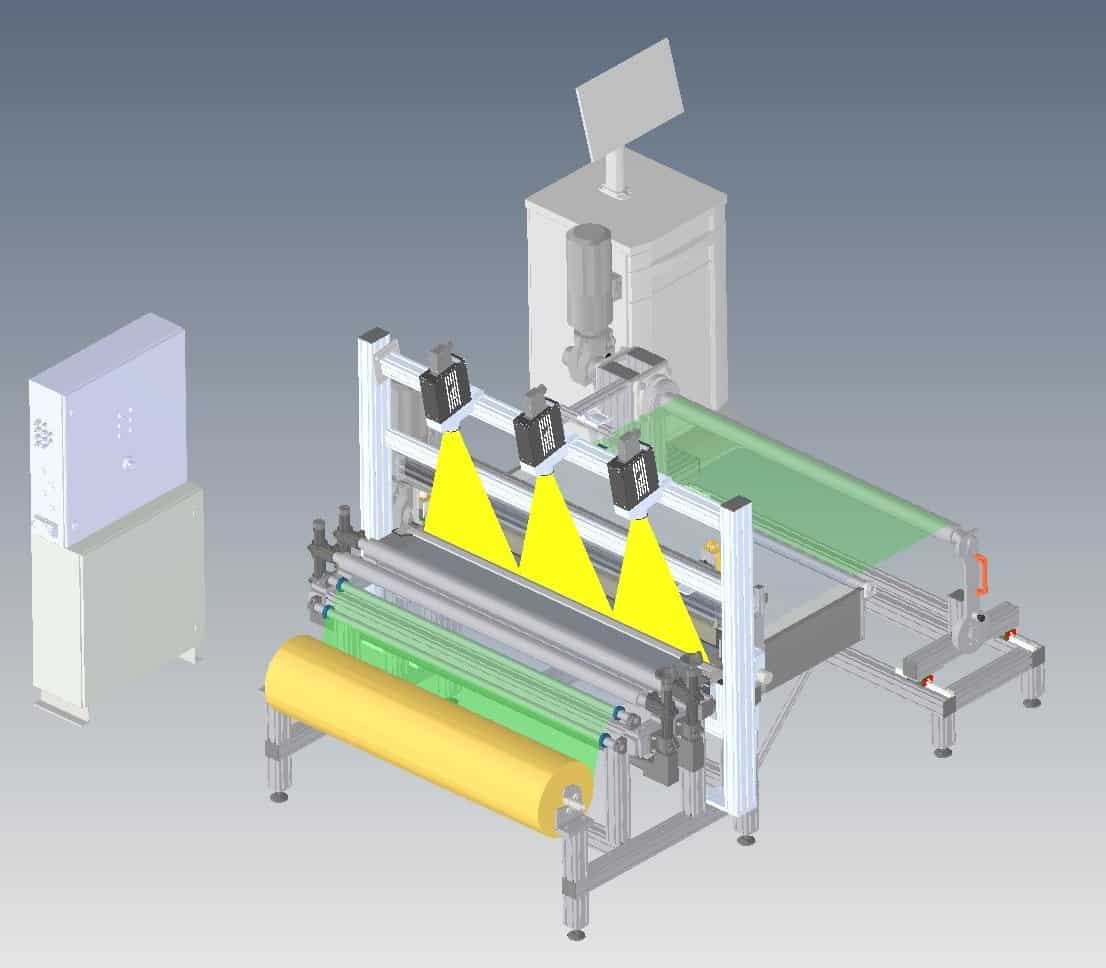

The AccuPore Mesh Analysis Inspection Service is an important process where the quality control for woven mesh is fulfilled by using a high-tech camera system. This mesh analysis system consists of high-resolution line scan cameras, which take continuous images of the mesh. As the mesh is exposed to the cameras, it identifies and tracks defects, including large openings, small openings, broken wires, physical damage and more.

Each mesh has its own properties, such as individual light transmission and reflection properties, which we refer to as the grey value. AccuPore Mesh Analysis Inspection can identify a wide variety of mesh and thus uses individually adapted defect detection algorithms, which lead to an outstanding repeatability and accuracy.

Many global industries often rely on certain wire mesh specifications for high performance use. Wire mesh is used for oil and gas, food and beverage, pharmaceuticals, critical separation, critical filtration, and more, were the specifications must meet specific requirements. At Porous Metal Filters, we understand the importance to meet specific requested criteria. We routinely provide custom manufactured specifications and verify wire cloth above and beyond industry standards. Our mesh analysis assures that specifications are met consistently.

Which Mesh Can Be Inspected?

- For defects: All specifications

- For mesh count: All specifications

- For opening size, wire diameters and open area: Plain and Twill Weaves

Dorstener Wire Tech also offers Glass Bead Testing for opening size inspections on a wide variety of mesh.

What Defects Can We Identify with Mesh Analysis?

In wire mesh we can identify the following, but are not limited to:

AccuPore Mesh Analysis by Inspection Services

This mesh analysis inspection system includes a fully automated roll winding mechanism, as well as an edge detection sensor for even better results. It is also equipped with a fully automated flaw detection system, which provides a defect analysis report of the rolls or sheets. The AccuPore Mesh Analysis Inspection system consists of multiple cameras for defect detection and to measure the openings, wire diameters and open area and weave patterns.

Overall, our company enjoys the capability to develop products according to our customers’ specific request. Porous Metal Filters is equipped with advanced mesh analysis inspection instruments and equipment to guarantee the quality control of our products. PMF manufactures wire products for a wide range of industries and applications. For many of these industries, product inspection and compliance are critical. In addition, with global raw material supplies, it is essential to know you are getting the quality and grade of material that you specified. PMF has the expertise and resources to ensure product compliance.

Porous Metal Filters is ISO 9001 Certified, and all our products are manufactured to the highest quality standards. Our staff is available to help you design the wire filtration product that will meet your design requirements and budget. Contact us today for more information about our products.

Your One-Stop Solution for Advanced Filtration and Metal Fabrication

We invite you to explore and discover how PMF can transform your filtration and separation challenges into opportunities for growth and success. Join us on this exciting journey as we reshape industries, one innovative filter at a time. Together, let's unlock the true potential of porous metal filtration. Give us a call, stop by for a free tour of the facility, or fill out our contact form and we'll gladly assist you.

Find Exactly What You Need

COMPANY

INDUSTRIES & APPLICATIONS

Automotive

Bulk & Powder Handling

Chemical Processing

Chromatography

Crude Oil Processing

Filtration Industry

Fuel Cells & Re-Formers

Gasification

Hot Gas Filtration

Industrial Filtration

Industrial Water Management

Irrigation Filtration

Liquid Filtration

Noise Abatement

Oil & Gas

Pharmaceutical

Plant Oil Extraction

Power Generation

Renewable Energy

Aerospace Filters

Ballast Water Filters

Chemical & Industrial Spargers

Chromatography Frits

Demineralizer Filters

Flame/Spark Arrestors

Flood Filters

Fluidizing Media

Gasification Filters

Hot Gas Filters

Irrigation Filters

Metallic Filter Cartridges

Metallic Memberane Support for Hydrogen

Nutsche Filters

Porous Metal Plate

Sand Screens

Sintered Metal Fiber

Sintered Wire Cloth

Temporary Strainers & Baskets

CAPABILITIES

Porous Metal Filters provides solutions for industrial filtration, separation, flow control, noise reduction, powder fluidization, and other applications through our SINTERPORE® brand of diffusion bonded (sintered) porous metal materials. Porous Metal Filters’ goal is to utilize its extensive experience to promote porous metal filters for the next generation of advanced filtration and separation products.

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(833) 707-9222 toll free

(281) 719-1352 local

(281) 719-1351 fax